Description

Nitrocellulose Laquer: “NITORLACK “RELIC” GLOSS

Nitrocellulose of high rigidity, with which different types of quarters can be obtained on the surface of the guitar.

It is therefore very easy to obtain the typical vintage effect of the 60’s typical of Fender and Gibson guitars.

- Crazing occurs within a few days of applying the product.

- If a more pronounced cracking is required, it can be achieved with further temperature changes on the surface of the guitar.

It is recommended to combine with a ratio of 40% Lacquer gloss and 10-15% solvent to obtain a less “aggressive” cracking. - As the ratio of Relic increases the cracking will become more pronounced and deeper.

- To enhance cracks and weathered appearance, it is recommended to combine with Relic Patina.

Varnishing process:

- If the wood of the guitar comes without previous varnishing, we will have to close completely the pore and cover the grain of the wood, until leaving it totally smooth, using for it several 4-6 coats of Nitorlack Primer (Nitro Primer).

- However, if the body of the guitar has already been varnished before, it will be easier as you only need to sand and apply a thin coat of Nitorlack primer.

- Apply the chosen colour, sanding between coats to leave the surface uniform and without imperfections.

- We start applying the relic finish in thin coats

- After this process you can apply two to three thin coats of Nitrocellulose Relic, sanding between coats until the surface is covered.

- The process up to this point is the same as the one used with the Lacquer Gloss.

- It can be polished before starting to break nitro.

- We wait about 15 days before starting the second phase:

Relic process:

- We put the guitar at a temperature between -10 and -20 degrees Celsius, in 4 hour intervals.

- As soon as the guitar comes out of the cold, it will have transparent cracks, so we apply RELIC PATINA with a cloth and clean it, leaving only what remains inside the cracks.

- This product should be removed within 3 to 5 minutes after application. This will make it easier to remove the excess, as it will not have dried completely.

- Leave the guitar at room temperature for 4 to 6 hours.

- You can repeat the cold and Relic Patina process as many times as you like. The more times you do it, the more pronounced the quarting will be, but 4 to 6 times should be enough.

Important: The spray is ready for direct application. However, the 1 litre can needs to be combined with 40% Lacquer gloss and 10-15% solvent, to obtain a less “aggressive” cracking. The higher the Relic ratio, the more pronounced and deeper the crazing will become.

With the guarantee of Valresa Coatings S.A.

Vintage inspired guitar colors!

Based on original F*nd*r and G*bs*n colors. To develop our guitar colors we have relied on original samples from the 50s and 60s. After great work and exhaustive study by our laboratory and technical department, some have been achieved guitar colors that faithfully recreate the tones of vintage Fender and Gibson guitars for painting electric guitar. During those years to the present, it should be borne in mind that the colors of vintage guitars have varied greatly over the years due to the aging of nitrocellulose lacquer and changes in the colors of the marks. Therefore two guitars finished in 1960 with fender colors today can be totally different from each other or from a more current guitar.

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

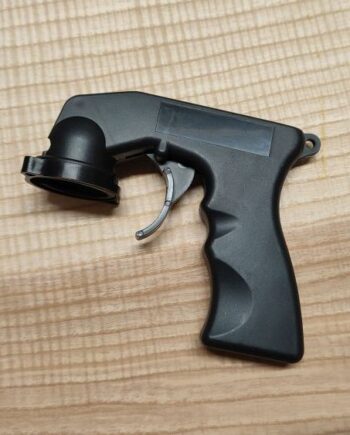

It is recommended to dilute the product with solvent to adjust the viscosity and that the application is perfect, we have two types of solvents. The usual solvent used is Solvent Medium , but for more extreme humidity and temperature environmental conditions we can use Solvent Retard to avoid boiling and veiling in the finish. The optimal application conditions are between 15 and 25 ºC of temperature and 50 to 70% humidity. The dilution percentage will depend on the painting equipment and its configuration, but the recommended is between 10 and 20% solvent. The most common gun peak is 1.3 to 1.5 and the compressor pressure is about 2.5 to 3 bars.

(All informations taken from the manufacturer)